Owns and operates Westech Automotive, Inc., a machine shop and vehicle repair service business located in Silver Lake, WI.

But before you have to pay for your mistakes, learn from the ones I made

The main purpose of previous columns has been to discuss the effects of OBD II on engine rebuilding. But one question many of our readers keep asking is "how real is this stuff?" Does OBD II really make that much difference in the way late model engines should be rebuilt?

Take my word for it, it's real. OBD II is something every rebuilder has to consider when rebuilding late model engines because of the way tolerances can affect emissions and misfire detection.

There's a sign in my office that reads, "Experience is what you get when you didn't get what you wanted." In other words, we learn from our mistakes. What you don't know can often get you into trouble, so learn from my experience and save yourself some headaches. Over the years, we've worked on a lot of different engines in our shop. We've done stock engines, performance engines and a lot of cutting edge projects, including performance development for some vehicle manufacturers. We've done Viper V10 performance packages as well as GM LS1 engine programs.

A number of years ago, I bought and restored a 1965 SuperStock Dodge A990 with a 426 hemi. The car runs consistent 11.20s in the quarter mile. We restored the engine using all original parts, and by paying careful attention to tolerances we ended up with better drivability than stock.

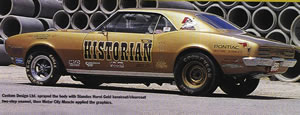

One project we did recently for General Motors was a street performance 1968 Firebird. The project was called the "Historian". The basic idea was to build a streetable exhibition drag car using a Ram Air III 455 engine. Some Pontiac engineers bet me the car would never meet emissions. I took their challenge and said it would meet 1975 standards. It turned out we were both wrong. With the converters on the engine it was actually able to meet 1990 emissions levels - and still runs 11.60s in the quarter mile!

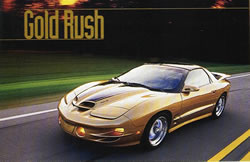

Goldrush

GoldrushShortly after we finished that car, we did another project for GM. We were asked to build a performance stroker motor for a 1998 Pontiac Tran Am project car called the "Goldrush". We installed a stroker crank in the LS1 engine to bring the displacement up to 382 cubic inches. The engine's power output increased from a stock 300 hp at the rear wheels on the dyno to 425 hp.

With the converters on, the engine would still pass an I/M 240 emissions test, so there was no sacrifice in emissions or drivability. By carefully matching the heads, camshaft and compression, we were able to crease an engine that was very drivable on the street, delivered gobs of torque with no significant increase in emissions.

But, we also learned something from this project that we hadn't anticipated. To our surprise, the MIL light would come on unexpectedly and log a P0300 "random misfire" code. Yet the engine was running smoothly with no detectable ignition misfire.

The OBD II system on this vehicle monitors changes in the speed of the crankshaft to detect misfire. Anything that causes even the slightest variation in the acceleration of the crankshaft between power strokes can mislead the OBD II system into loggin what it thinks is a misfire. As the "misfires" add up for the various cylinders, it eventually reaches a threshold that triggers the MIL light and logs a random misfire code.